Take a breath.

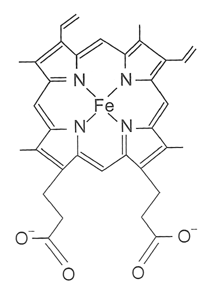

The iron in your blood is carrying the oxygen you just breathed to your entire body, where each oxygen molecule releases so you can live. Iron is the central atom of every heme group in your blood, and the atom of iron is necessary for oxygen bonding. Without those iron atoms, you would die.

Take another breath. The iron atoms in your blood come from one source: the supernova of a star. All the iron on earth - and there is a lot of it, iron is the most abundant element on earth - comes from stellar supernova, or stellar nucleosynthesis. Iron is thus the sixth most common element in the entire universe. Your hemoglobin comes from those stars. And so does your cast iron skillet, your grape arbor, lots of the parts in your car, and all the steel in modern cities.

We are all the product of supernovas.

The word for iron in Indo-European languages actually comes from a non-Indo-European one: Etruscan. In Etruscan, iron is aisar meaning "the gods." (ok how cool is that??) From aisar we get the Old English eisern and then to the modern word iron.

The many different iron ages that sprang up in history developed with not the smelting but the carburization of iron. Smelted iron is fairly weak; heat it over and over with lots and lots of pounding, and you get wrought iron, and then heat that slowly over charcoal with a quenching in hot oil, and you get a surface of steel. Blacksmithing was born. (All that charcoal does indeed turn you black.) The earliest iron age in the world began in Eastern Niger in Africa around 1500 B.C.E., making it the earliest known iron smelters in human history. Archaeologists have found carbon steel in Tanzania, dating it to 2000 years ago, making these the earliest steel findings in human history.

In Europe the iron age begins with Halstatt Culture around the 8th century B.C.E. By 500 B.C.E. the Celtic La Tene culture exploded iron production into all aspects and tools of culture. As Celtic culture spread across Northern Europe, the iron technologies spread as well. Iron is intrinsic to Celtic society, and the Celts brough Europe into the iron age. And as we know, the earlier cultures and then the Celts, proceeded to bung all their lovely iron into wells and bogs and rivers and lakes.

I want to look at the magic of ironworking itself, though, long before offering the knife or sword to a Goddess.

I know a modern smith who smelts his own iron, collected from rocks on his property. He then forges the iron into what is similar to medieval wrought iron. Then he pattern welds the wrought iron with heat, pounding, and carburizing to create steel. His period authentic knives and swords have many a historical re-creationist salivating!

As a beginner smith, I get to watch this stuff while I learn the beginning techniques of making the fires, heating steel, learning to use my hammer and tongs. (Tongs are everything. . . and I hope within the next year to start making my own.) At a recent SCA open forging event, I had reached the point where Bjorn helped the other newbies while, vivat!, I got to work with some low carbon steel and forge a shawl pin all by myself. I burned a huge blister on my thumb - through gloves no less, but for the first time did not drop my piece all over the place, and in very little time had a very primitive shawl pin. ("It's not symmetrical," Bjorn pointed out. I had to grin and tell him, "I know." "Don't you want to fix it?" "No.")

Yet while I worked at my beginning level, Bjorn took an old wrought iron piece from a manure spreader, heated it and worked it down, and pattern welded a piece of steel. The heat and hammering opens the low carbon wrought iron, and he added extra mass and carbon with folding in band saw blades. Flux (household borax typically) is used to keep oxygen from the welding. Then the process of pattern welding re-formed the molecular structure of the wrought iron, from the grainy, pliable wrought iron, into a much stronger piece of metal that will eventually hold an edge, be incredibly strong, while retaining flexibility. Watching an old piece of manure machinery turn into pattern welded steel is magic.

As I've written before, it is a magic that women have learned for centuries. Yet in all the wonderful pagan and Christian webpages out there, I see little to encourage women into blacksmithing. And the SCA forge was a more typical smithing atmosphere than my wonderful antique tractor group. Yes the boys talked endlessly about who has the bigger hammer and sticking stuff into the fire and who is the cutest babe on Mythbusters. A dear Bridget loving Christian friend of mine has suggested I start snapping tongs about as a means to stop this kind of sexist banter. (He himself is a master carpenter and just assumes I have the technical skill to snap tongs in a threatening manner! However, it is a great suggestion, and I will keep practicing!)Anyway, no, I wouldn't want my son or daughter listening to this stuff while they learn smithing.

So what I hope to do is to get my gentle readers, male and female, into blacksmithing, and I hope I can bring encouragement to all to explore this amazing craft. It is magic in front of your eyes! And it is not all that expensive. Bjorn likes to head into the woods and smelt his iron and hammer on rocks. At the same SCA event I came home with a used hammer and a piece of railroad track for an anvil. A pair of tongs and some heat resistant bricks and some charcoal and I am in business. Yup, you can use hairdryers for bellows. Propane forges are as cheap as $200 on ebay if you don't want to make your own. I know a lovely youtube link for making a forge with a cheap $20 weed burner, which I already have. Yes, amazing pattern welded steel takes time to learn. But shawl pins and candle holders are easy to learn in a few days.

So consider blacksmithing! It's an art, it's fun, it's sacred to Bridget.

It's also amazing magic.

(Take another breath. . . you have it in you already. . .)

No comments:

Post a Comment